We customise your Big Bags

Versatile additional equipment for FIBCs

FIBCs (Flexible Intermediate Bulk Containers), also referred to as Big Bags, are now used across the board in many different industries. As Big Bags need to be designed to suit the individual on-site situation and the relevant task, we offer a range of customisation options. We can equip your Big Bag with a lifting, filling and emptying system, document pocket or inliner and also a seam seal if required. What’s more, we can also print a suitable company logo or catchy advertising slogan on Big Bags.

Lifting systems for simple transportation of Big Bags

Lifting systems enable the transport sacks to be lifted very easily, and therefore quickly and efficiently. We offer a range of lifting systems to meet various customer requirements: Accordingly, Big Bags can either be equipped with lifting loops developed exclusively for transportation with forklift trucks, or with multifunctional lifting systems that enable the transport sacks to be lifted by forklift truck and also grippers or cranes.

In addition to lifting systems for lifting the Big Bag at four points, we also offer – depending on the required filling weight – Big Bags with only one lifting loop, or with two lifting loops, and also Big Bags with side-seam loops.

Filling and discharging systems for easy filling and discharging of FIBCs

Different filling and discharging systems are available, depending on the material – large stones, course granular material or fine powder – to be filled in the Big Bag and also the discharging method.

Document pocket – display information clearly on transport sacks

In Big Bags equipped with a closable filling system it is not possible to tell what is inside the transport sack from the outside. With a DIN A3, A4 or A5 document pocket, information on the content of the Big Bag can be made available to employees by displaying it on the outside. Employees can now see what is inside the transport sack without having to open it. The visibility of relevant information – regarding content, transportation or storage – can be increased by putting document pockets on two, three or all four outer sides of the transport sack.

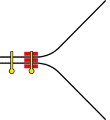

Reliably seal the seams of Big Bags

If FIBCs are to be used for the transportation of finely powdered material, we recommend sealing the seams. This keeps the content of the Big Bag free of dust and other external contaminants. It also prevents the content from leaking out through the seams. The seam may need to be sealed on one, two or three sides, depending on the nature of the filling material.

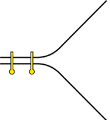

standard seam

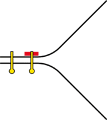

seal on one side

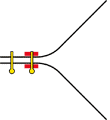

seal on two sides

seal on three sides

Inliner provides reliable protection of filling material

Inliners – like seam seals – play a significant part in keeping the content of the Big Bag free of dust and also keeping out moisture. They are also suitable for transporting moist material because they are exceptionally tight.

The practical inliners are especially popular in the food, chemical and pharmaceutical industry because they can simply be exchanged, providing they are not sewn or glued to the Big Bag. This is particularly useful when manufacturing food, for example, to avoid contamination: Big Bags with discharge spouts can, for example, be used to dispense different ingredients – without no labour-intensive cleaning of the Big Bags required – thanks to the exchangeable liners.

At RuGo Bags we offer the following inliners:

- Inliner with side folds

- Shaped inliner

- Shape-retaining inliner

- Inliner inserted loose and sewn to filling opening

- Inliner sewn at eight points

- Inliner sewn with wings

- Full-surface glued inliner

Dimensions and volume of a customised Big Bag

The dimensions of customised FIBCs are essentially based on the requirements of the relevant company and the on-site situation. To be able to calculate the dimensions or the volume of a Big Bag, the following information is required:

- Calculating the volume, restriction due to maximum weight: We can calculate the volume of the Big Bag based on the information provided by the customer about the material to be transported or stored in the Big Bag and the required maximum weight of the filled Big Bag.

- Calculating the volume, restriction due to dimensions of storage space: If customers want to use the Big Bags to store materials, the height of the storage space and the dimensions of the available floor space are relevant when calculating the volume of the Big Bag.

- Calculation of height based on specified surface area: On the other hand, if we know what the available surface area is and which volume is required, we can calculate the height of the Big Bags.

Calculation of surface area based on specified height: If there are restrictions on the height of the Big Bag, we can determine the possible surface area of the Big Bag when additional information about the required volume is available.

Using Big Bags with logos for outdoor advertising

The opportunity to use any potential advertising surface should not be missed. We therefore recommend that, whether these are Standard Big Bags or customised Big Bags, our customers print a slogan or company logo on the Big Bags. We can manufacture Big Bags with company logo from a minimum order quantity of 50–100 units.

Take advantage of our expert advice now

We are happy to give you comprehensive advice on the various customisation options we offer for Big Bags. Together with you, we will configure the Big Bag to match your individual requirements.

You can buy Standard Big Bags directly from our online shop. You can order woodbags and potato bags, for example, from us online.